Quality Policy

Committed to provide top quality

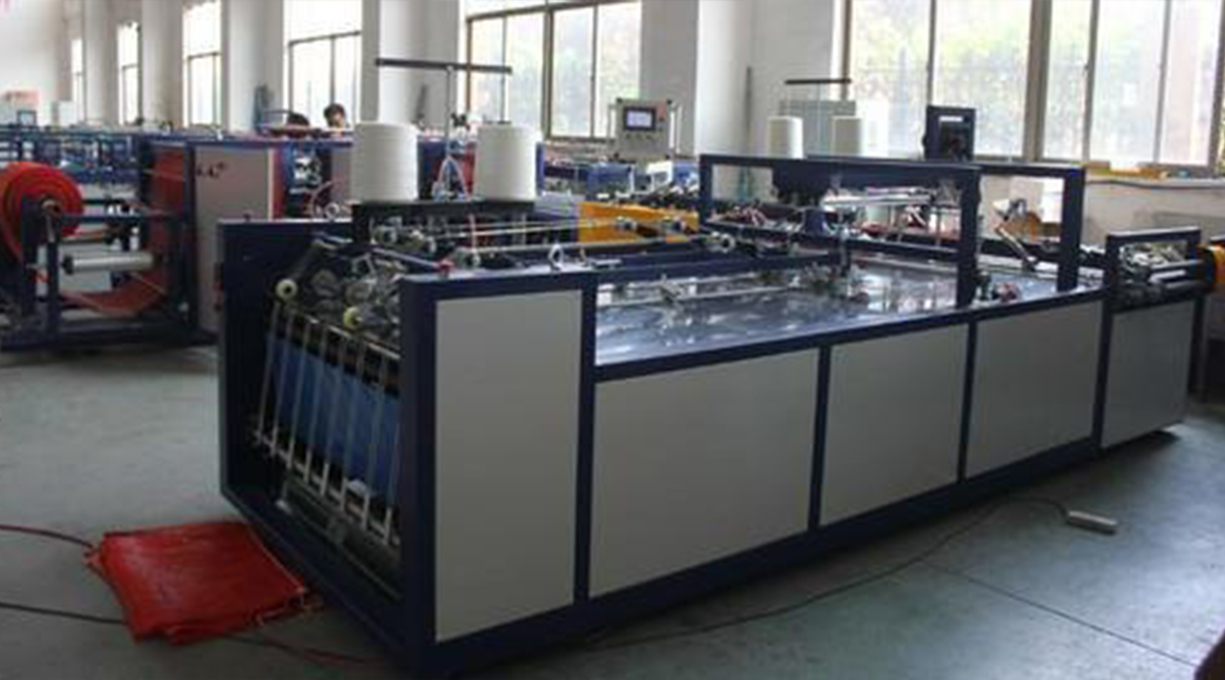

At Green Polypack, we believe in stepping and attaining an extra mile. With a continuous process of quality improvement and commitment to comply with international quality norms, we established long term relationships with many of our valued clients winning their trust through innovative products, unmatched quality and dedicated support services. Backed by well equipped latest technologies used by our highly skilled & experienced team ensure that the products we maintain adhere to international quality standards and offer superlative performance.